Designed to The Building Regulations BS 5268 Part 3 and other building standards for vertical restraint. Light Duty Restraint Straps are generally for vertical applications such as holding down the wall plate. Both light and heavy duty straps are produced from galvanised mild steel, and also from stainless steel. Restraint straps and banding is a set of high-quality products designed to reinforce connections between structural elements of a building, in horizontal, lateral and vertical restraints. The turn-down should be on a substantial piece of blockwork, preferably the centre of an uncut block.

Straps should go under rafters and over ceiling joists. Rafters should not be notched to make the straps flush with the rafter. The fixings should be four steel screws or four 75mm x 4mm (8 SWG) round nails. Restraint straps should be fixed to solid noggings with a minimum of four fixings of which one should be in the third rafter. In higher buildings straps should be spaced at not more than 1.25m centres. They should be installed at not more than 2m centres for buildings up to three storeys (two storeys in Scotland). Restraint straps are required to provide stability to walls. Restraint Straps shall be used to restrain gable and separating walls and hold down the roof against wind uplift. Restraint Straps should be of sufficient length to be fixed to three trusses and should be fixed with solid blocking. Lateral restraint straps should have a minimum cross section of 30mm x 5mm and a minimum anchorage downturn of 100mm. Larger gable or separating walls may also require restraint at ceiling level. For dwellings of masonry construction,restraint should be provided at rafter level for gable walls. Appropriate metal restraint straps should be used.

In situations where the roof is required to resist uplift, skew nailing is unlikely to provide sufficient strength. For trussed rafterroofs not subject to uplift, the minimum fixing should be two 4.5mm x 100mm long galvanized round wire nails, skew nailed, one from each side of the trussed rafter. The trussed rafter roofs and traditional cut roofs should be supported on timber wall plates. Use corrosion resistant nails (3.Building, in horizontal, lateral and vertical restraints.Engage at least three rafters with each strap.Nailing a strap (or even screwing it) into position while the masonry is green is difficult to do without disturbing and weakening the blockwork. Straps can be built into the masonry in their correct positions and temporarily tied to the rafters allowing noggings and packing to be added later.

Straps can be fixed before the gable is built, but great care is needed to ensure that downturns are in line and match with coursing. Nail each strap to at least three rafters and to the timber noggings, which are needed between the rafters (as shown right).

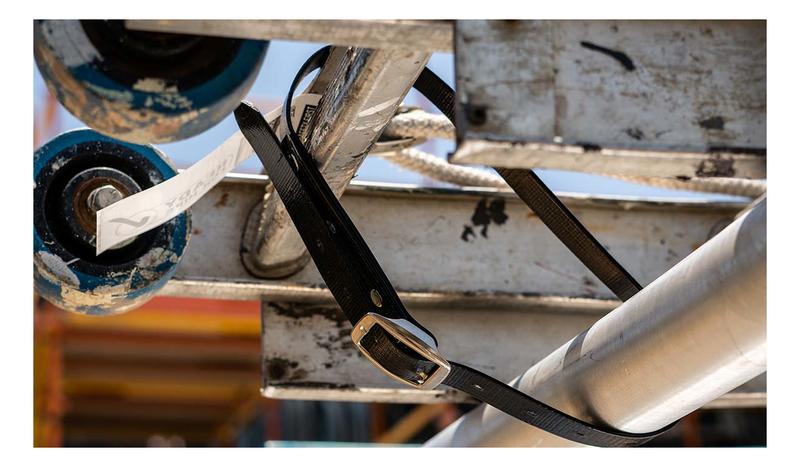

#Rafter straps full#

They must engage a full block on a gable, and will need to be fitted to the underside of the rafter members. Straps provide most of the lateral stability to the gable wall and are nearly always required.

0 kommentar(er)

0 kommentar(er)